Introduction:

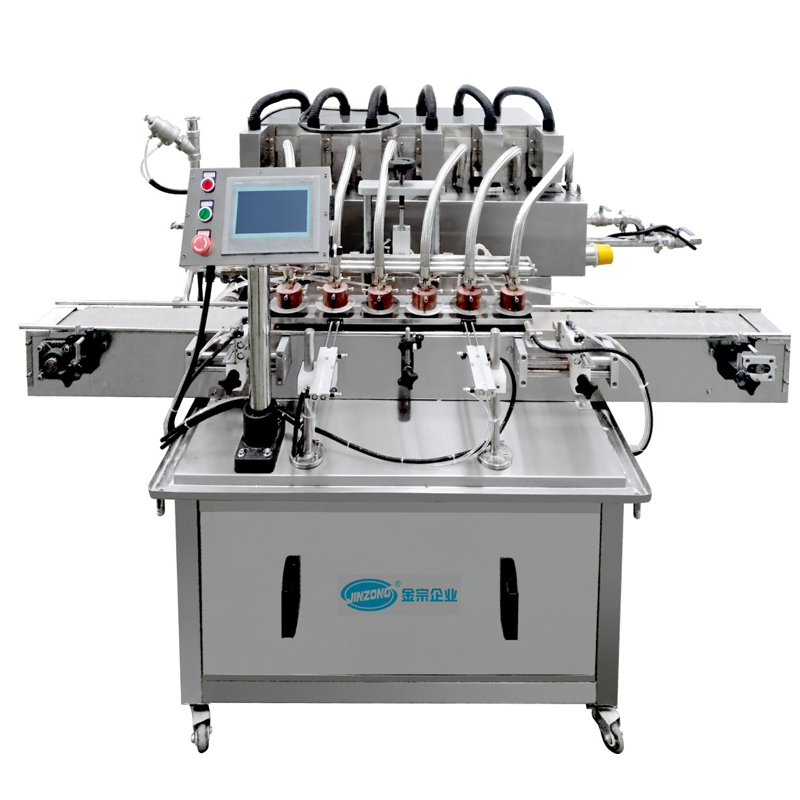

This equipment is mainly used for the filling of BB cream, including monochrome, bi-color, and tricolor BB cream. It has its own insulation function. Under low temperature conditions, it will not affect the fluidity of the material body because of the temperature, thus ensuring the filling effect, and It has good interchangeability. Easy cleaning, simple maintenance, accurate filling, high efficiency.

Features:

1, self-insulation system, under low temperature conditions to ensure the fluidity of the material body, so as to ensure the accuracy of the product filling;

2, work high efficiency, hourly output can reach 1800-2400 bottles;

3, for different thicknesses of the material body can be filled, single/double color: 6000-8000 PCS(C); Tricolor: 6000-13000 PCS(Libo);

4, the operation is simple, there is no need to train the operator, equipment workflow: manual bottling-automatic filling = automatic pressure cotton-manual inner ring-automatic pressure inner ring-sucker grab put to the production line;

5, the material storage and circulation part is the use of food grade, safe and hygienic.

Note: Low density sponges can be used with equipment.

Work flow: manual square box-automatic filling-secondary pressure cotton-hand square inner ring-pressure inner ring-take out conveying-marking machine.