The heating mechanism of the reactor covers a variety of technical approaches to adapt to different working conditions and temperature control needs.Below,Jinzong Enterprise for everyone to popularize several common heating methods,each way has its unique advantages and application scenarions:

1.Water Heating

Water heating is an economical option when the reaction temperature is mild and there is no strict requirement for heating rate. It is particularly suitable for specific working conditions that require heating and cooling cycles and ultimately require a return to room temperature. The specific operation is to first use hot water for preliminary heating until the set temperature is reached, then discharge hot water, introduce cold water for cooling, and achieve flexible temperature control.

2.Steam Heating

Steam heating is another widely used heating method that is suitable for different temperature ranges depending on the type of steam:

Atmospheric steam is suitable for reaction conditions not exceeding 100℃.

Saturated steam is suitable for heating at 100~180℃.

Superheated steam can cope with high temperature requirements of more than 180℃.However,the implementation of steam heating requires the corresponding steam boiler facilities to ensure a continuous and stable steam supply.

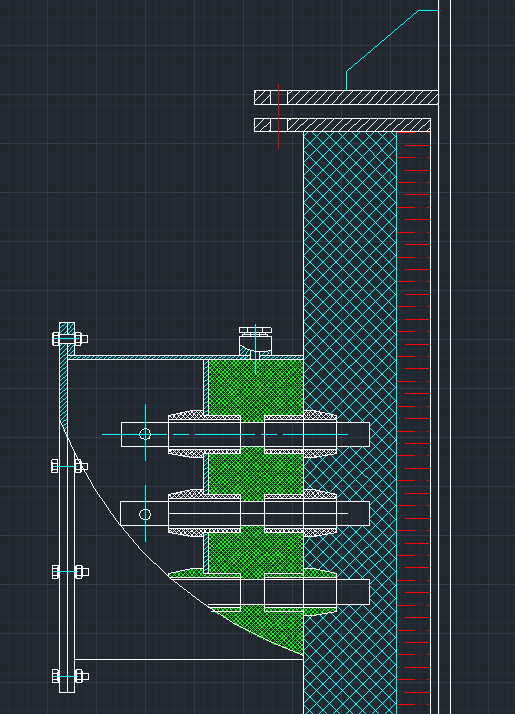

3.Heat Transfer Oil Heating

Heat transfer oil heating technology is divided into two main modes:

Heat transsfer oil circulation system,which requires a heat transfer oil furance to transfer heat to the reator through an external circulation.

Jacketed heat transfer oil heating,that is ,the interlayer of the reactor is filled with heat transfer oil,and the built-in electric heating rod directly heats the oil body,and then heats the materials in the reactor through heat conduction.This method provides stable and efficient heat transfer.

4.Electrical Heating

Electric heating methods, especially electric heating rods or heating belts, are favored for their convenience and controllability. However, the upper temperature limit of this type of heating element is about 250 ℃ (the silicone heating strip without load is about 200 ℃), which makes electric heating more suitable for medium and low temperature reaction processes. Its main components include electric heating materials and insulation layer, ensuring high efficiency and safety.

5.Far Infrared Heating

Far infrared heating technology utilizes far-infrared radiation to directly act on the surface of materials, converting them into internal energy through resonance absorption of molecules and atoms, achieving rapid and uniform heating of materials. This non-contact heating method not only has high heating efficiency, but also effectively reduces heat loss, making it particularly suitable for scenarios with special requirements for material surface heating.

In summary, the selection of heating method for the reactor needs to be comprehensively evaluated based on various factors such as reaction conditions, cost budget, safety considerations, and energy efficiency. Each heating technology has its own uniqueness, and the correct choice can greatly improve production efficiency and product quality.

|

联系我们

全国服务热线 肇庆一分厂:广东省肇庆高新区(大旺)康泰街3号 肇庆二分厂:广东省肇庆高新区(大旺)建设路36号 E-mail: jinzong@jinzong.com.cn

|