Synthetic resin is a type of high molecular weight polymer generated by monomer polymerization without any additives or with only a small amount of additives. It is the basic raw material for manufacturing synthetic fibers, coatings, plastics, adhesives, insulation materials, etc. It is widely used in agriculture, construction, automotive, mechanical, electronic and other fields, and is the highest production and consumption synthetic material in the world.

At present, there are still a large number of resin production enterprises in China that use manual feeding, manual measurement, manual temperature control and other production methods. The degree of automation in production is insufficient, the equipment is old, the failure rate is high, and the production efficiency is low. At the same time, there are also significant safety hazards. There are technical bottlenecks in resin production equipment for drip addition, temperature control, and mixing systems, making it difficult to support high-end resin production. This has led to overcapacity in China's basic resin production, while high-end and special resins still rely on imports. There is still a certain gap in the production process of high-end resins compared to developed countries abroad.

In order to promote the transformation, upgrading, and development of enterprises, the Ministry of Industry and Information Technology and seven other departments jointly issued the Notice on Issuing the Implementation Plan for Promoting Equipment Updating in the Industrial Field, promoting the safe transformation of old chemical equipment, promoting digital technology, and developing new quality productivity. At the same time, it is also necessary to properly understand the safety risks of old equipment such as reactors and storage tanks, and improve the essential safety level of the industry.

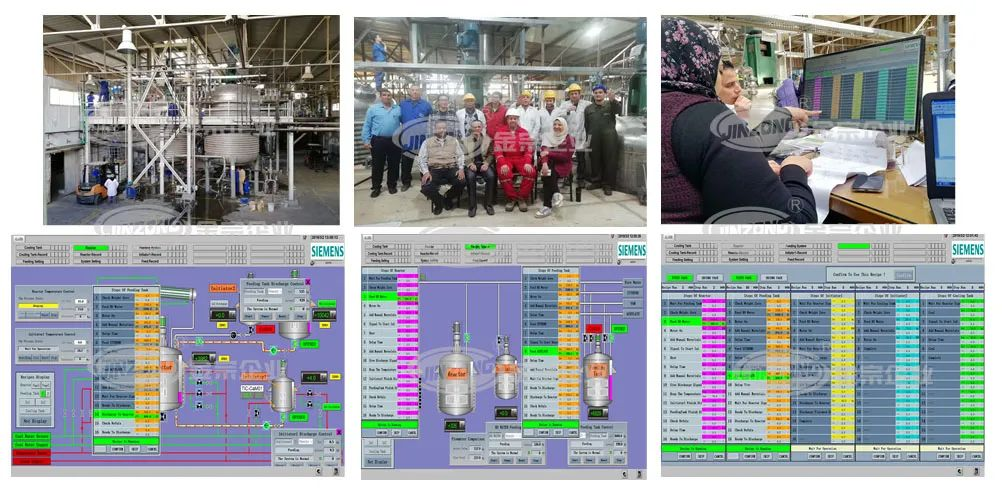

The resin complete set of intelligent equipment independently developed by Jinzong Enterprise is automated throughout the production process, with automatic intelligent measurement, drip addition, and efficient and stable pre polymerization preparation. It can achieve instant strong emulsification, efficient desolvation, high solvent recovery, automatic water replenishment, and easy cleaning. Relying on the Internet of Things system, real-time monitoring of the operation of each device, daily report formation, factory operation status, clear at a glance, achieving factory intelligence and digitization. We can provide customized design according to the customer's process requirements, project engineering design, equipment selection guidance, equipment processing, equipment installation, and other turnkey engineering services. It can meet the needs of mid to low-end production, ensuring safety, environmental protection, energy conservation, efficiency, and stability; It can also provide the optimal solution of technical solutions, meet high standards and cutting-edge process routes, develop new quality productivity, help customers improve product competitiveness, and achieve high-quality sustainable development.

Jinzong resin complete set of intelligent equipment system

Jinzong resin complete set of intelligent production line adapt PLC control system,to realize the automation,intelligence of the whole production,through the special surpporting storage tank,conveying equipment,metering equipment,the raw materials are transported to the reactor,after dissolution,reaction,refining,dissolving,filtration,drying and other processes,and finally made into resin finished products and automatic filling.

1.Reaction device and control systems

According to reaction types and the temperature required,the reactor is equipped with heat transfer system,stiring device and sealing system,the fully automatic control system ensures that the raw materials are fully mixed and constant reaction conditions are maintained.

2.Material storage and metering systems

Before production,materials are stored in dedicated tanks,through accurate metering equipment, different raw materials are transported to the reactor in accordance with the formula ratio, and the feeding process is automated.

3.temperature and pressure control

Resin synthesis process on temperature and pressure is very stric,the equipment is equipped with temperature control system,vacuum system and pressure control system.temperature control system using coil,jacket and other methods of heating or cooling,according to requirements of customer,choosing electric heating,oil heating,steam heating, etc.

4. separation and purification equipment

The synthesized resin may contain incomplete monomers, solvents or by-products, which are distilled, fractionated or extracted by vertical condensers, horizontal condensers, water separators and other equipment in order to purify the resin product.

5.Filtration and drying

The filter removes impurities from the resin and the drying equipment further removes moisture or solvents to ensure the quality and performance of the resin product. Optional equipment includes: plate and frame filter, bag filter, centrifugal separator, etc.

6.Packaging and transportation

After the above steps to obtains a resin products that meets specification,through filling equipment to package, then it is transpored to the storage area through the conveying equipment to achieve fully automatic dischage and filling.

Properties and characteristics of resin production equipment

1. Automatic weighing and measurement, intelligent drip add

In the process of resin production, the quality and safety of resin production are greatly affected by the control of drip adding technology. Dripping mixed materials too fast, may lead to too much reaction, too fast, the temperature rises sharply, the phenomenon of boiler flushing, and even may occur safety accidents; The drop acceleration is too slow, which may lead to uneven reaction and affect product quality.

The full set of production equipment of Jinzong resin adapts to weiging sensor control system,according to real-time data of automatic feeding process control, the rate of change of flow or weight is calculated, and according to the rate of change PID algorithm, the closed-loop control valve opening is used to control the acceleration and accuracy of material drops. All weighing, drip data record, big data analysis and optimization, to achieve the whole process automation, intelligence, accurate control of material drip, reduce labor, reduce labor costs, reduce safety accidents, improve product quality.

2.Optimize the temperature control system to achieve reduce cost and increase efficincy

The resin reaction can only be carried out under certain temperature conditions, and during the reaction process, it must be maintained within a stable temperature range. However, when the material is added to a certain amount, the reaction speed accelerates and the heat release is intense. At this time, the temperature is the most difficult to control and is recognized as a control difficulty in the industry.

Jinzong Enterprise has optimized the structure of the coil and jacket, strengthened temperature control by accurately controlling the temperature and flow rate of the heating oil and cooling book, and applied for multiple invention patents. At the same time, the temperature control system has also been intelligently transformed. Through the monitoring and calculation of big data in the background, the trend of temperature rise and fall demand has been predicted, and the temperature rise and fall strategy has been activated in advance. The temperature has been upgraded from passive control to active control, achieving automatic and accurate temperature control within ± 1 degree. Production efficiency has been improved by 60%, product quality has been improved by 50%, and labor costs have been reduced by 50%.

3. Self-developed high efficiency mixing, reduce sticky wall blockage

A stirring system independently developed and possessing intellectual property rights, which selects different stirring paddles according to customer needs to meet the mixing needs of various materials with different viscosities, making the mixing of materials more uniform and the reaction more complete. At the same time, it reduces wall sticking, prevents resin from clumping or blocking the discharge port due to insufficient stirring, facilitates cleaning, and reduces material waste.

4. Full process automation, safety, energy saving and environmental protection

The Jinzong resin intelligent production line adopts an automation control system to achieve full process automation production, while monitoring the operation of each equipment in real time, forming daily reports, and making the factory operation situation clear at a glance. The equipment has explosion-proof design and has passed the EU explosion-proof CE certification, ensuring safety and environmental protection. Good sealing performance, no leakage, low failure rate, guaranteed quality, and long service life.

5. Personalized customization, wide range of application

The complete set of resin intelligent equipment is suitable for large-scale, medium, and small-scale production. The modular design of each unit of the complete set of equipment allows users to purchase complete sets or units as needed, and personalized customization can also be made according to customer needs. We provide turnkey engineering services such as project engineering design, equipment selection guidance, equipment processing, and equipment installation.

The equipment has a wide range of applications and supports the preparation of oil-based and water-based resins, including but not limited to the production of the following materials: alkyd resin, polyester resin, unsaturated polyester resin, epoxy resin, acrylic resin, (PU) amino resin, curing agent, hot melt adhesive, adhesive, silicone oil, gloss oil, etc.

Establish a Chief Quality Officer system to strictly control product quality

Jinzong Enterprise regards product quality as its lifeline and strictly follows international quality management system standards such as ISO. Under the guidance of the Market Supervision Bureau, it has established a Chief Quality Officer system and established a comprehensive product quality control process, ensuring that every link in the entire chain from product design, raw material procurement, production manufacturing to finished product inspection is strictly monitored for quality.

The company is equipped with complete advanced quality testing instruments, such as material chemical composition analyzer, ultrasonic flaw detector, surface roughness meter, ultrasonic thickness gauge, infrared temperature measuring gun, electric spark detector, spectral analyzer, etc., to comprehensively and accurately control the production process and product quality, ensuring that every product is of the highest quality.

Supported by specialized and innovative enterprises, with guaranteed service quality

Jinzong Enterprise was founded in 1999, with over 20 years of experience in the production, research and development, design, and installation of chemical coating equipment. It has a design and marketing service center in Guangzhou and two production factories in the Zhaoqing National High tech Zone. It has the qualifications for special equipment pressure vessel manufacturing and pressure pipeline installation (GC2). It is a national high-tech enterprise and a provincial-level specialized, refined, and new enterprise. It has two provincial-level famous brand products, dozens of product patents, software copyrights, and provincial-level high-tech products. It has passed the national intellectual property certification, ISO9001-2015 international quality system certification, EU CE certification, and five-star after-sales service certification. For many consecutive years, it has been rated as a "Guangdong Province Contract abiding and Creditworthy Enterprise" by the Guangdong Provincial Administration for Industry and Commerce. Its technological research and development strength is strong, and it provides services. Credit is guaranteed, with users spread across more than 50 countries and regions worldwide, and has gained widespread recognition and support from over 2000 small and medium-sized enterprises at home and abroad.

To do a good job, one must first sharpen their tools. Jinzong Enterprise upholds the concept of "quality is like gold, craftsmanship is the core" and provides advanced and automated production lines to manufacturing factories. Friends from home and abroad are welcome to visit and guide us.

Contact number: 18022469891.

|

联系我们

全国服务热线 肇庆一分厂:广东省肇庆高新区(大旺)康泰街3号 肇庆二分厂:广东省肇庆高新区(大旺)建设路36号 E-mail: jinzong@jinzong.com.cn

|