Jinzong Enterprise Glycerol Edible Oil Production Line Helps Customers Achieve Scale Production

With the improvement of people's living standards and the formation of unhealthy habits, diseases such as obesity, cardiovascular disease, and fatty liver are becoming more and more common, which have seriously threatened human health. Fat is the culprit of these diseases, so the reasonable intake of oil in daily diet has become very important.

Recent studies have shown that diacylglycerol can inhibit the accumulation of fat in the body, play a role in reducing blood lipids, visceral fat, weight loss, and preventing cardiovascular diseases such as hypertension, coronary heart disease, diabetes, myocardial infarction. Triglycerides, as a multifunctional additive, have a wide range of applications in the food, pharmaceutical, and chemical industries.

However, its current application is far from reaching the potential level it should have, mainly due to the difficulty of large-scale industrial production of diglycerides, which are too small to meet market demand and therefore expensive, greatly limiting their application.

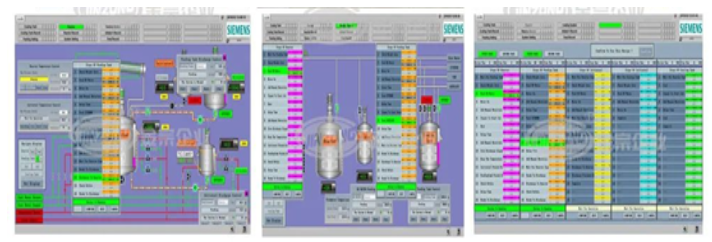

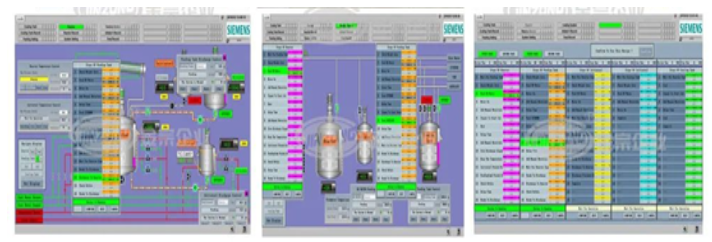

The diglyceride edible oil production line designed and produced by Jinzong Enterprise adopts a fully automatic intelligent production process, and all operations from feeding to discharging are completed through computer operation. Most processes adopt closed automatic operation, which is time-saving, labor-saving, energy-saving, and environmentally friendly. Using computer and PLC control, the operation is intuitive, the control is accurate, and errors can be automatically corrected, which can assist customers in achieving industrial scale production.

The main components of the diglyceride edible oil production line

The glycerol diglyceride edible oil production line mainly consists of reaction kettle, ingredient tank, distillation tank, centrifuge, plate and frame filtration, storage tank and other equipment, which can achieve multiple processes such as enzymatic hydrolysis, esterification, multi-stage distillation, impurity removal, decolorization, deodorization, and filtration.

Performance and characteristics of a production line for diglyceride edible oil

1. Automatic feeding, precise control of feeding ratio

Fully automatic feeding, equipped with an automatic measuring system, precise control of feeding ratio, can meet strict ingredient ratio requirements, and ensure product quality.

2. Accurate temperature regulation provides a favorable reaction environment for enzymatic hydrolysis

Accurately adjusting temperature control facilitates real-time grasp of key parameters such as reaction temperature and pressure, providing a favorable reaction environment for enzymatic hydrolysis and esterification, and improving reaction efficiency.

3. Specially made mixing slurry to meet the production needs of different processes

Specially designed for the production line of diglyceride edible oil, the stirring slurry and speed can meet the production needs of different processes. Through adjustable speed frequency converters, multiple stirring and other methods, the contact surface of the materials is expanded to achieve rapid, full, and uniform mixing, improving the efficiency and quality of enzymatic hydrolysis and esterification.

4. Good hygiene performance, in compliance with GMP and FDA specifications

The equipment material is made of 304 stainless steel or 316L stainless steel, and the entire production process is sealed, safe, environmentally friendly, and hygienic, fully complying with GMP and FDA specifications. The cleaning work is convenient and fast, which can effectively avoid secondary pollution of the product.

5. Small footprint and high space utilization rate

The equipment design is compact and occupies a small area. Can conduct on-site surveys, design production line layouts based on actual conditions, make reasonable use of site space, and assist customers in reducing costs and increasing efficiency.

Supported by specialized and innovative enterprises, with guaranteed service quality

Jinzong Enterprise was founded in 1999, with over 20 years of experience in the production, research and development, design, and installation of food and pharmaceutical equipment. It has a design and marketing service center in Guangzhou and two production factories in the Zhaoqing National High tech Zone. It has the qualifications for special equipment pressure vessel manufacturing and pressure pipeline installation (GC2). It is a national high-tech enterprise and a provincial-level specialized, refined, and new enterprise. It has two provincial-level famous brand products, dozens of product patents, software copyrights, and provincial-level high-tech products. It has passed the national intellectual property certification, ISO9001-2015 international quality system certification, and EU CE certification. For many consecutive years, it has been rated as a "Guangdong Province Contract abiding and Creditworthy Enterprise" by the Guangdong Provincial Administration for Industry and Commerce. Its technological research and development strength is strong, and its service credit is guaranteed, with users scattered throughout. More than 50 countries and regions around the world have gained widespread recognition and support from over 2000 small and medium-sized enterprises both domestically and internationally.

To do a good job, one must first sharpen their tools. Jinzong Enterprise adheres to the concept of "Quality is like Gold, Craftsmanship is the Core" and provides advanced and automated production lines to manufacturing factories. Friends from home and abroad are welcome to visit and guide us. Contact number: 13798112675.